Heat Resistant Conveyor Belt

Product Description:

Heat Resistant Conveyor Belt

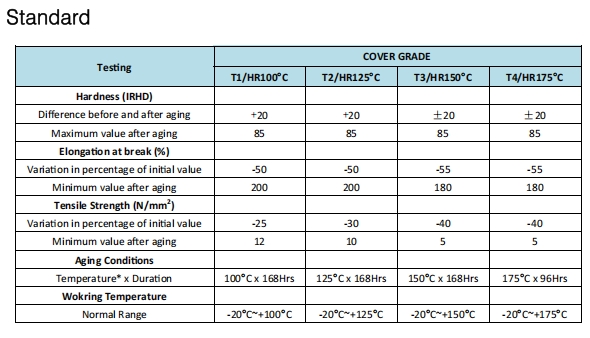

Features

Conveying high temperature materials, like coke, sinter returns, quick lime, cement material…

Carcass: EP, high modulus low shrinkage EP, steel cord, or IW

Cover Compound: SBR or EPDM

Applications: Grains & Sugar Conveying, Foundries, Cement Industry, Recycling Plants, Steel Industry, Chemical Industry, Power & Petrochemical Industry, Coke Plants, etc..

Key Points: Type of carried material, Shape of carried material, Lump size of carried material, Temperature of carried material, Temperature of belt surface, Belt speed, Length of conveying system, etc.

Links:

Copyright © AG ORIENTAL MATERIAL SUPPLIES CO., LTD All rights reserved